On August 1st 2024, the BMWK-funded research project FloatStructure officially started. Andreas supports ESOS Wind GmbH in the conceptual implementation of the project. It forms part of the collaborative research initiative FloatModular, which aims to develop new floating offshore wind turbine (FOWT) concepts based on a modular and scalable support structure adaptable to different water depths and turbine sizes.

BMWK-funded R&D project CableProtect started

CFD support in the BMWK-funded research project DigitShip (2022-2024)

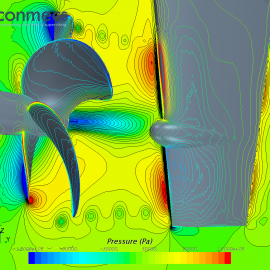

conmecs supports Siemens Energy in R&D project

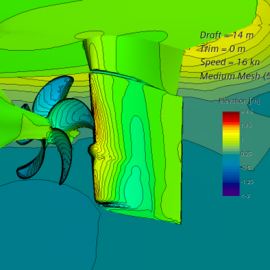

Siemens Energy Global GmbH & Co. KG is a leading global company that offers services for energy generation and transmission with a strong focus on renewable energies and solutions for the decarbonization of existing customer processes. Siemens Energy’s maritime division offers effective podded drives (PODs) for the shipping industry. Recently, Siemens Energy asked conmecs to support the CFD investigations in a R&D project.

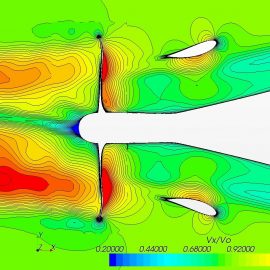

rudder loads

The design of rudders are usually based on class society rules. The required, minimum rudder area is estimated in relation to the ship’s wetted lateral hull area. Rudder profiles come from old, successful shipbuilding projects. Rudder designs are often developed by another supplier, regardless of the propeller manufacturer. The positioning hull-propeller-rudder is traditionally based on experience from old projects.

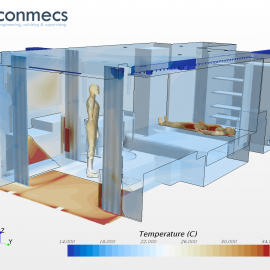

RANS simulations of air ventilation for AERIUS Marine GmbH

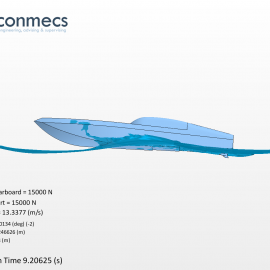

50″ motor yacht – performance in regular waves

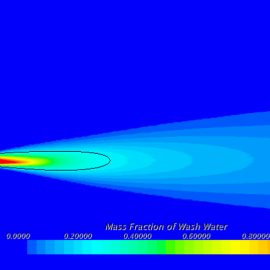

smoke gas propagation

The exhaust emissions from ships are not only discussed in terms of GHG (greenhouse gas) reductions. The operators of offshore supply vessels (OSV) are concerned about their technical employees who work primarily on deck and are exposed to the exhaust. In addition to these health matters, yacht and cruise ship operators want to avoid that passengers be disrupted by the smell of exhaust gases.

energy saving devices (ESD)

There are a lot of different energy saving devices (ESD) on the market, e.g. pre-swirl fins, ducts (Schneekluth, Mewis), and post-swirl devices (costa bulbs, rudder fins and hub fins). The suppliers promise efficiency rates, which lie within achieved rates of former projects and the spread is often relatively high, e.g. savings of “2 up to 6%”. For ship owners it is difficult to decide, which device is the best solution for their particular ship design.

proof of MEPC.259(68) compliance

According to MEPC.259(68) the pH discharge criteria of scrubber systems can be approved by computational fluid dynamics or other equally scientifically established empirical formulae. Conmecs provides the calculation and documentation according to these requirements. If desired, conmecs can also take over the communication with the associated class society.