About ten years ago the proper ventilation of perishable goods was an issue for some ship owners and operators. Many reefer cargo hold ventilation systems were designed with a weak performance and the cooling units of containers failed during transport due to intake temperatures above the cooling units maximum design temperature. This problem has been solved for many container ships due to the design of ventilation systems according to new regulations, which take into account conservative fresh air volume rates.

Nowadays, a detailed analysis of the air and temperature distribution in reefer cargo holds is under another aspect useful: energy saving opportunities!

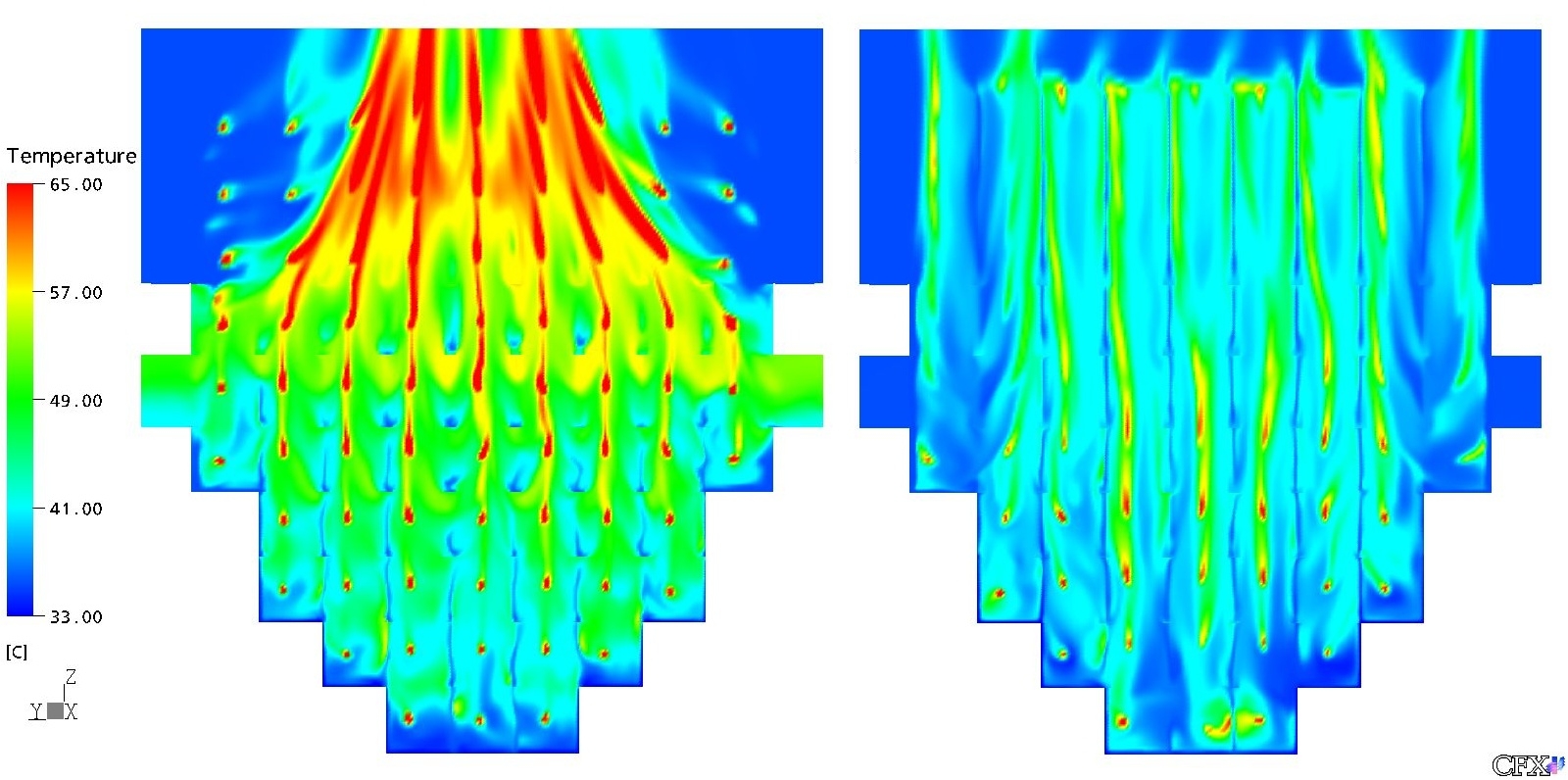

We offer detailed CFD-analyses of ventilation systems and predict energy savings by computing design variants with different inlet and outlet positions.